Knitting

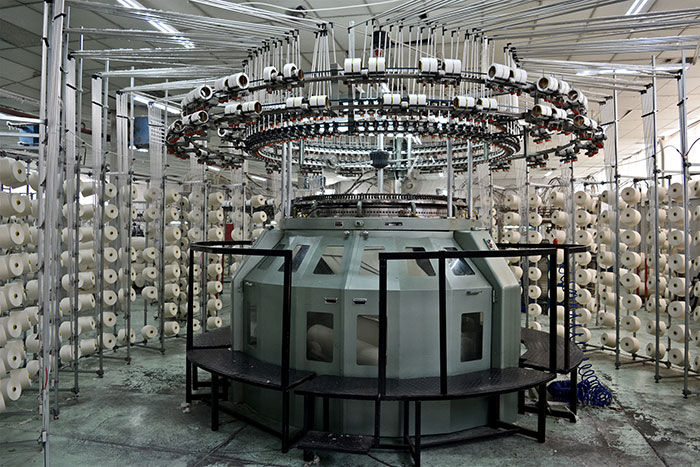

With an installation of 40 automatic and modern circular knitting machines has a significant production infrastructure with a monthly capacity of 150-180 tons of knitted fabric. The company produces and sells a wide range of knitted sheets based on cotton, polyamide, polyester, elastan yarns and their mixtures in order to produce its main fabric qualities Jersey, Terry (Frotte), Interlock, BIO Jersey (GOTS certified ecological yarns) and special qualities for charitable institutions (hospitals, nursing homes etc).

Dyeing- Finishing

The company has one of the biggest and modern dyeing houses with its 10 tone/day jet dye pad-batch capacity.

All the dyeing machines are followed online by a central computer system supported by an automatic dyestuffs and chemicals distribution system.

Finishing is the final processing where fabrics are softened, dried, ironed and get ready to be cut into the end product.

Confection

At this production stage, the technical team composes a highly detailed quality control which guarantees that the levels of quality expected by our clients are achieved. Moreover, a specialized team cuts the patterns in order the fabric to be converted into a wide range of products that satisfy our customers’ needs and orders. At the final stage, the ready products are packaged according to customers’ packaging qualifications.